New Arrival | Official Release of Fully-automated End-to-End NGS Solution Based on NadAuto-16R

View: 5446 / Time: 2024-08-29

01 Background

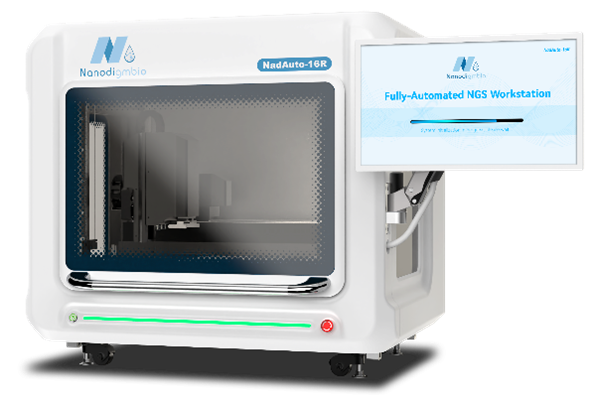

With the continuous advancement and widespread application of Next-Generation Sequencing (NGS) technology, both research and clinical practice have raised higher demands for the automation, stability, efficiency, and safety of experimental processes. Traditional manual operations in NGS workflows face various challenges, such as cumbersome process, complex operations, high requirements for personnel expertise, low throughput per single operation, and the risk of cross-contamination in open operating environments. Therefore, there is an urgent need in many laboratories for a new, higher level of automation in NGS workstations to extend unmanned operation time and reduce labor and time costs. NadAuto-16R Fully-automated NGS Workstation (hereinafter referred to as "NadAuto-16R") has emerged to meet this demand, combining extensive experience in NGS reagent development and usage to better fulfill the need for automation in the complex NGS workflow.

The launch of NadAuto-16R stems from a profound understanding of wet lab experiments in the entire NGS workflow and insights into the challenges in experimental operations. It is specifically designed by Nanodigmbio for the NGS applications, aiming to provide a more efficient and precise experimental tool to meet the market demand for high-throughput, high-quality experiments.

The end-to-end solution based on NadAuto-16R not only enhances the standardization level of experimental operations but also improves the efficiency of the experimental process while significantly reducing errors introduced by manual operations. NadAuto-16R is dedicated to providing researchers with a more intelligent and reliable experimental solution, empowering them to achieve more significant accomplishments in NGS applications.

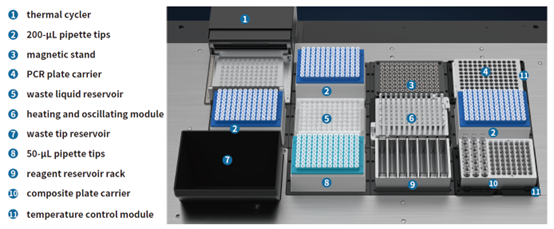

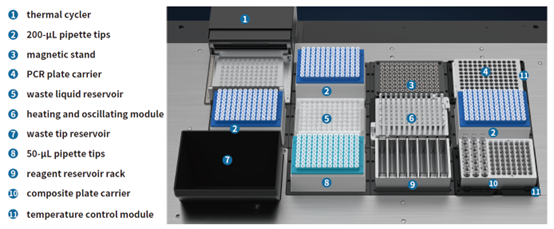

NadAuto-16R consists of a host, integrated terminal, and control software. The host comprises a 3D robotic arm, a liquid handling module, 2 temperature control modules, a thermal cycler, a heating and oscillating module, and a host frame. The host has 12 standard SBS built-in plate positions, allowing for the flexible combination of functional modules, carrier, and consumables to meet the needs of various scenarios and sample amounts. Meanwhile, it is accompanied by a liquid handling module with 8-channel pipetting tips and a plate gripper, supporting the loading of 1/8 pipette tips, enabling flexible configuration based on the samples amounts, thus enhancing efficiency and facilitating plate transfer effortlessly.

Figure 2. Dynamic deck layout for NadAuto-16R.

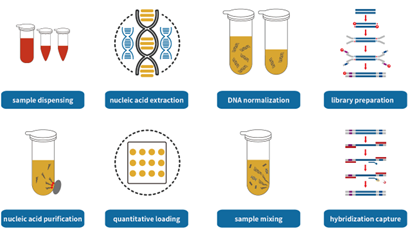

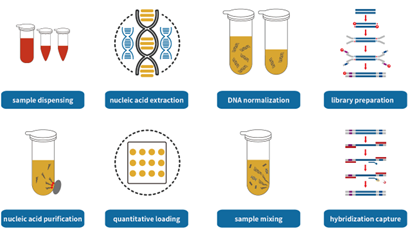

NadAuto-16R is not only applicable to automated sample processing and loading, including sample dispensing, nucleic acid extraction, enzyme reaction system preparation, nucleic acid purification, quantitative loading, and sample mixing, but also for automated preparation of gene sequencing libraries and hybridization capture in clinical diagnostics, which can comprehensively enhancing laboratory efficiency.

Compact and Portable

Occupies less than 1 m3 of desktop space, effortlessly fits in limited spaces.

Integrated design of terminal all-in-one and mainframe, saving installation and operational space.

Flexible Integration

Seamless integration of temperature control module, heating and oscillating module, and thermal cycler on the dynamic deck, supporting the flexible configuration of high-throughput workstation to true walk-away automation.

Multi-functional integrated modules create a professional-level NGS automated workstation with minimal user errors.

Flexible combination of 8-channel pipetting tips for precision pipetting, meeting diverse liquid-handling requirements, and improving pipetting efficiency.

User-friendly Simplicity

3D Mobile Robot with 8-channel pipetting tips and plate gripper, equipped with preset multiple transfer tracks, effortlessly handling liquid transfers and plate movements.

High-definition large LCD screen, flexible touch control with quick response, one-touch start/pause/resume processes to sustain workflow.

Graphical process editing, guided operation, drag-and-drop script elements, zero-threshold visual programming for a more user-friendly human-machine interaction.

Preset for routine applications such as NGS library preparation and hybridization capture, ready to use upon purchase. Meanwhile also supporting personalized customization and independent script development.

Secure and Reliable

Standard equipped with HEPA and UV lamp, ensuring continuous cleanliness of the operating environment.

Based on a liquid-free air displacement pipetting principle, effectively removing aerosol contamination.

Bright, highly colored status light bar indicates the host's operating status in real time, thus avoiding hardware failures and software errors that can cause long downtime.

Multi-level permission management ensures data security by assigning different operation permission levels to various users.

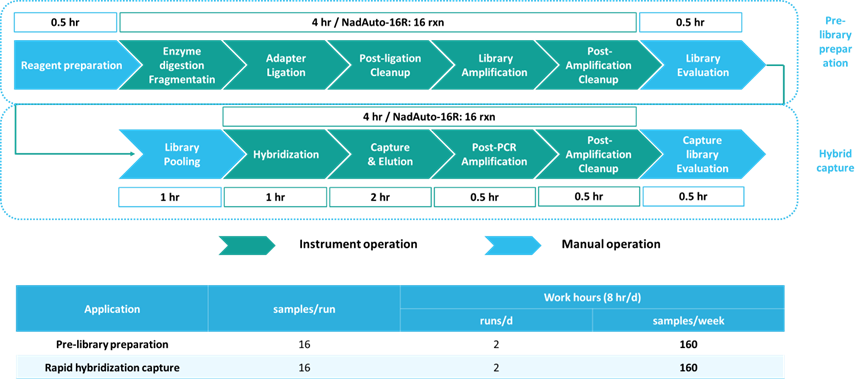

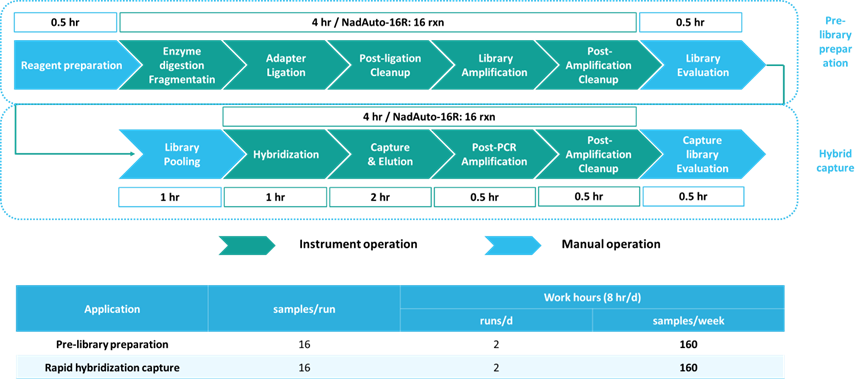

NadAuto-16R is compatible with full series of library preparation and hybridization capture reagents from Nanodigmbio. Based on the built-in scripts of the instrument, it can deal with a throughput of up to 16 samples per run for library preparation and 16 reactions per tun for hybridization capture. In addition to reagent preparation and library quality control, it essentially achieves fully automated wet experimental operations, extending unattended operation time to improve work efficiency.

Automated operations are performed on NadAuto-16Rutilize built-in scripts of the instrument. All manual operations are performed in accordance with the user manual.

Hybridization capture: The multi-hybridization reaction was initiated with 500 ng of each pre-library with the same pre-library preparation scheme. Thecapture was performed by using LungCancer Panel v1.0 with NadPrep ES Hybrid Capture Reagents (1 hr for hybridization). 8 samples per batch. 1 Gb of data was selected for analysis.

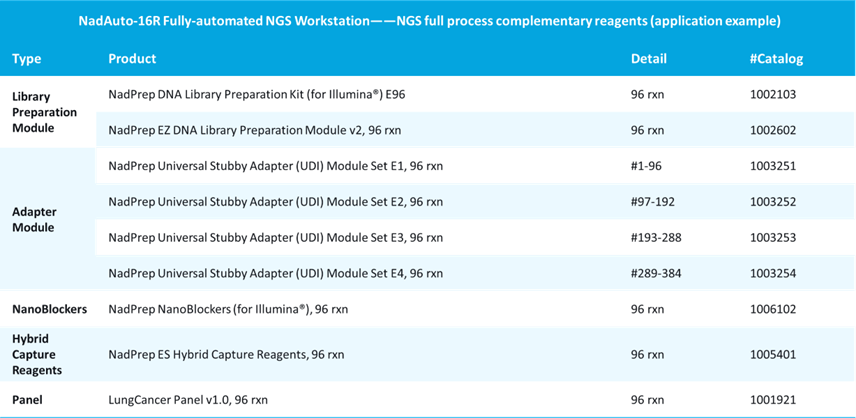

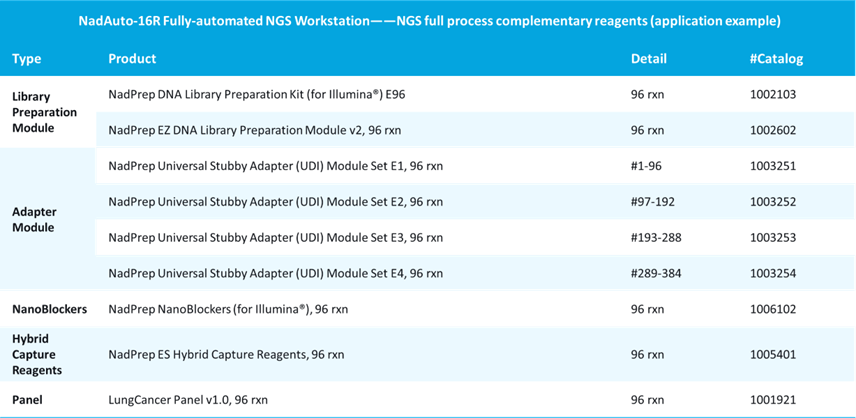

Table 1. Complement reagents of automated NGS application on NadAuto-16R.

4.2 Performance

4.2.1 Performance of pre-library preparation in different batches (8 samples per batch fragmentated by sonication)

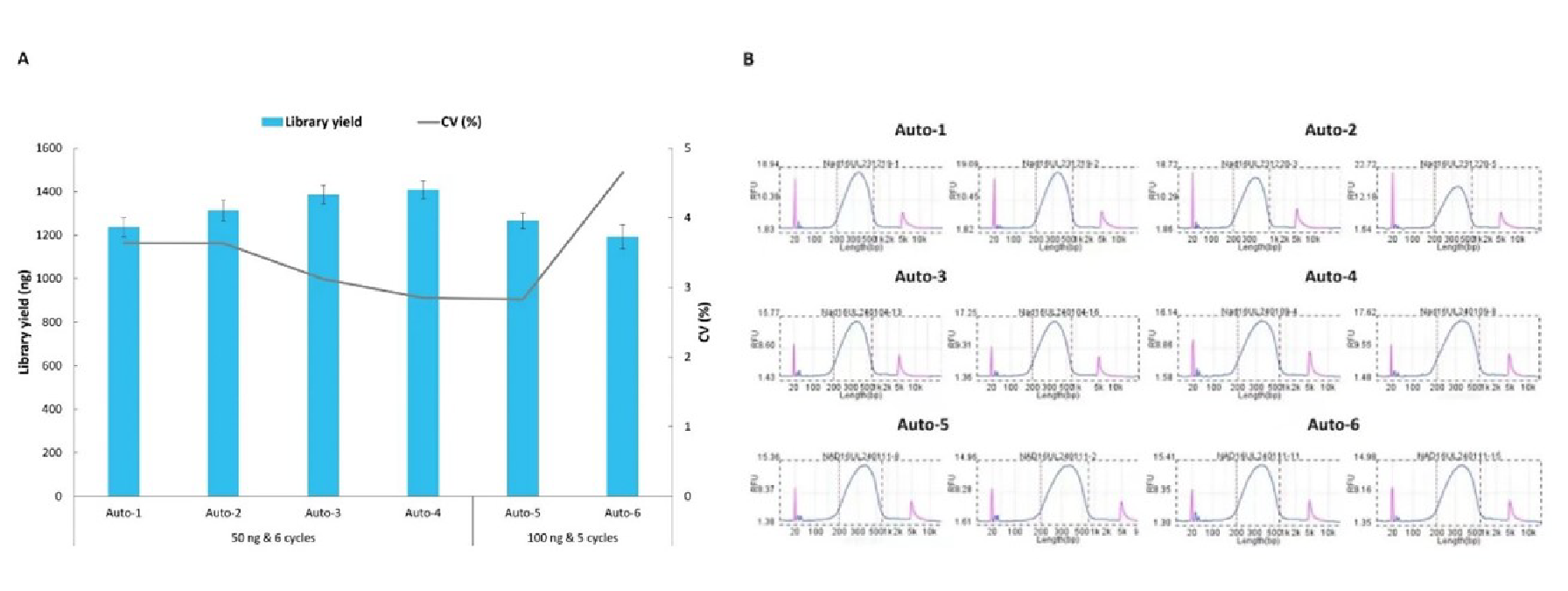

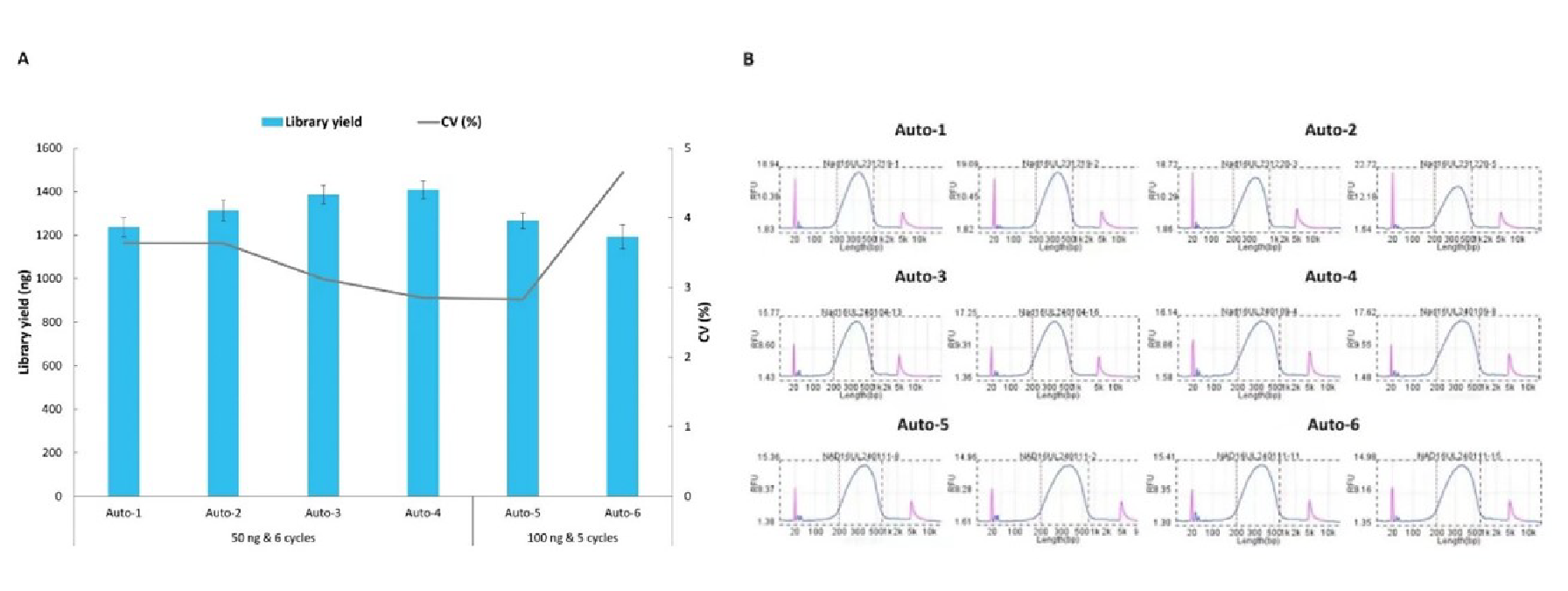

Pre-libraries preparation were performed in each batch using 50 ng and 100 ng of human genomic DNA standards (Promega, G1471) fragmentated by sonication respectively, with 8 samples per batch. The results showed good stability of library yield across different batches, with average library yield ranging from 1192.9 ng to 1,409.6 ng (Figure 5.A), and the CV value (%) ranging from 2.826 to 4.650. In addition, after library preparation in each batch, we randomly selected 2 libraries for Qseq quality inspection (Figure 5.B), which showed that the size distribution of insert fragments in the libraries was within the expected range, consistent with the parameters recommended in the user manual.

Figure 5. Multiple-batch library yield and size distribution of the whole-genome libraries with sonication fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA Library Preparation Kit (for Illumina®) coupled with the NadPrep Universal Stubby Adapter (UDI) Module.

Figure 5. Multiple-batch library yield and size distribution of the whole-genome libraries with sonication fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA Library Preparation Kit (for Illumina®) coupled with the NadPrep Universal Stubby Adapter (UDI) Module.

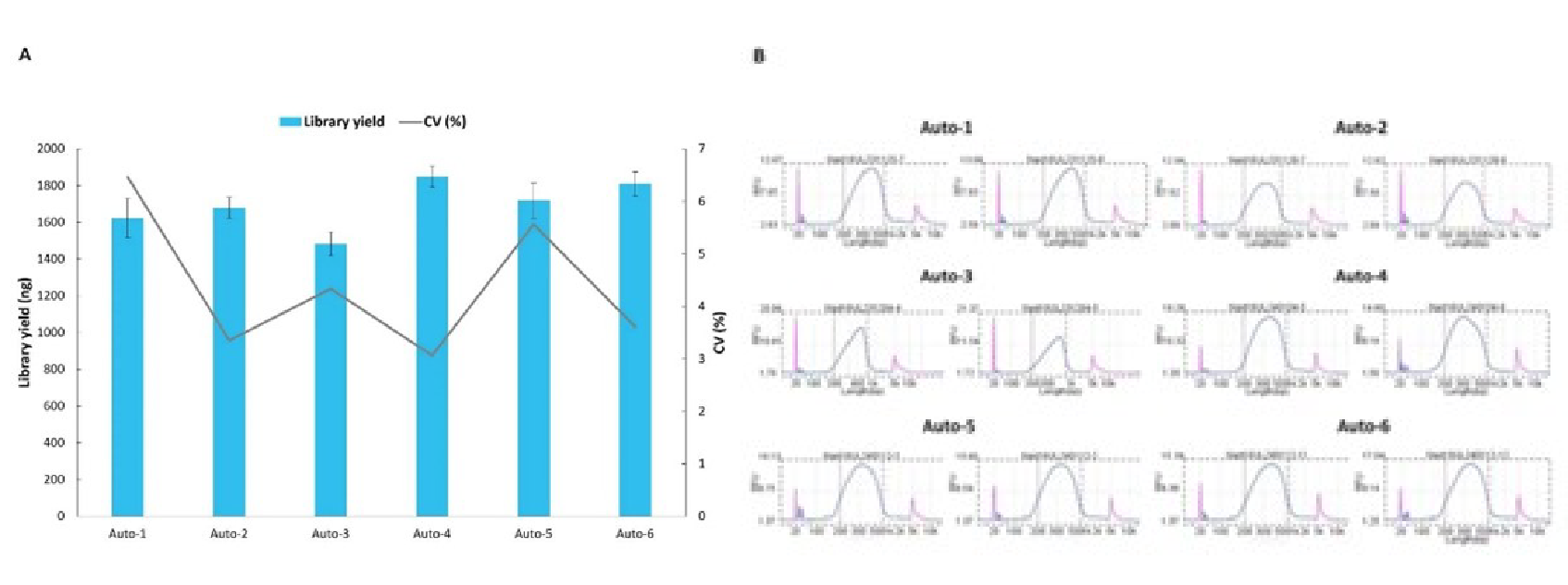

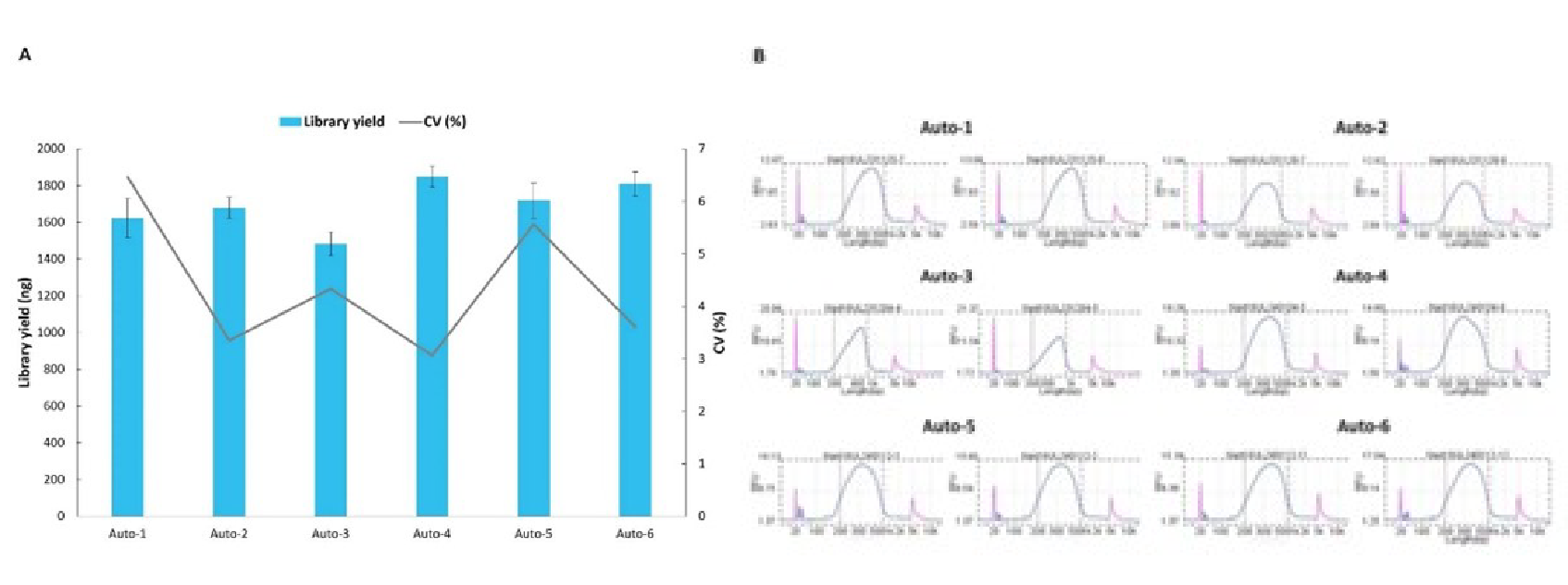

4.2.2 Performance of pre-library preparation in different batches(8 samples per batch fragmentated by enzyme)

The results showed good stability of library yield across between 6 batches, with the average library yield ranging from 1473.6 ng to 1,848 ng (Figure 6.A), and the CV value (%) ranging from 3.068 to 6.566. In addition, after library preparation in each batch, we randomly selected 2 libraries for Qseq quality inspection (Figure 6.B). The results showed that the insert fragment distribution of the libraries was within the expected range, consistent with the parameters recommended in the user manual.

Figure 6. Multiple-batch library yield and size distribution of the whole-genome libraries with enzymatic fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module.

Figure 6. Multiple-batch library yield and size distribution of the whole-genome libraries with enzymatic fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module.

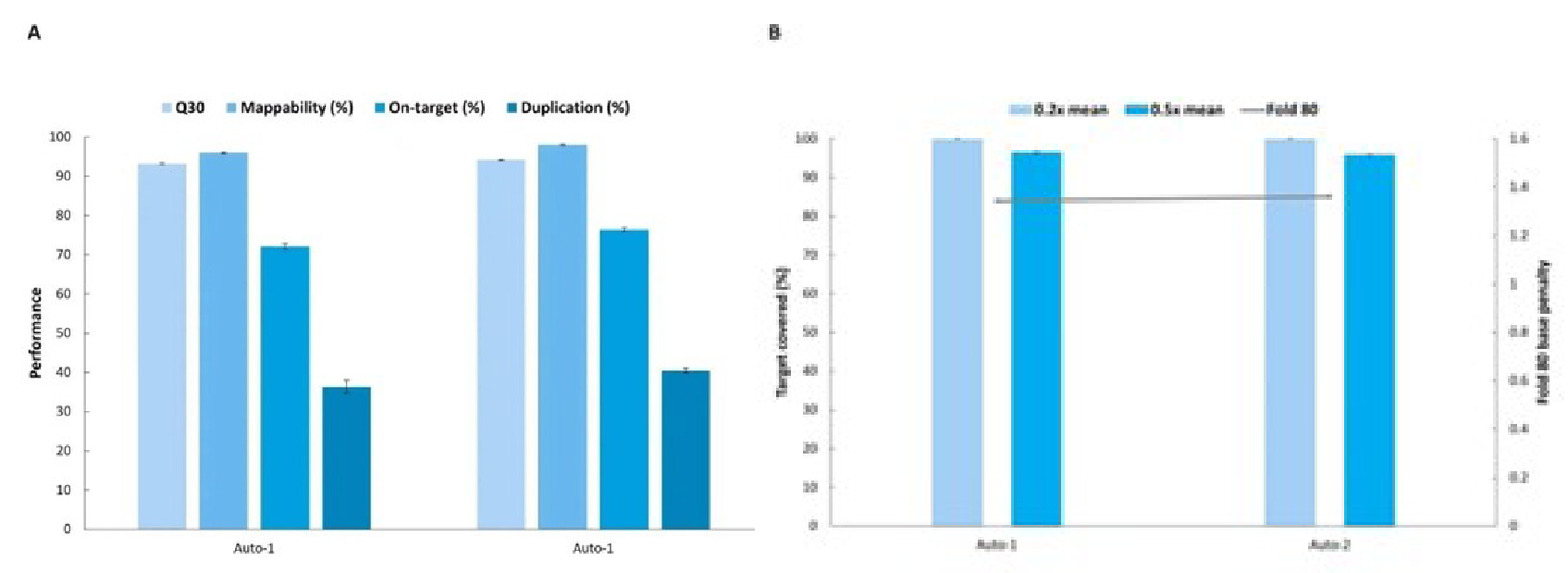

4.2.3 Performance of captured library preparation in different batches (8 samples per batch)

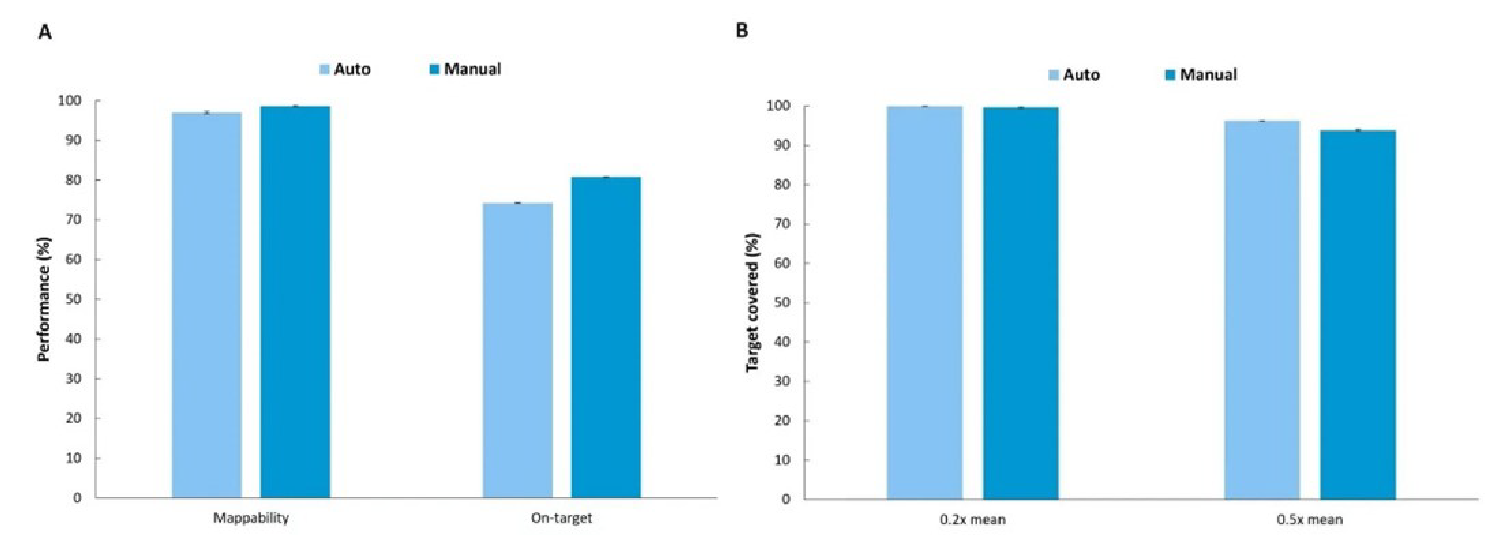

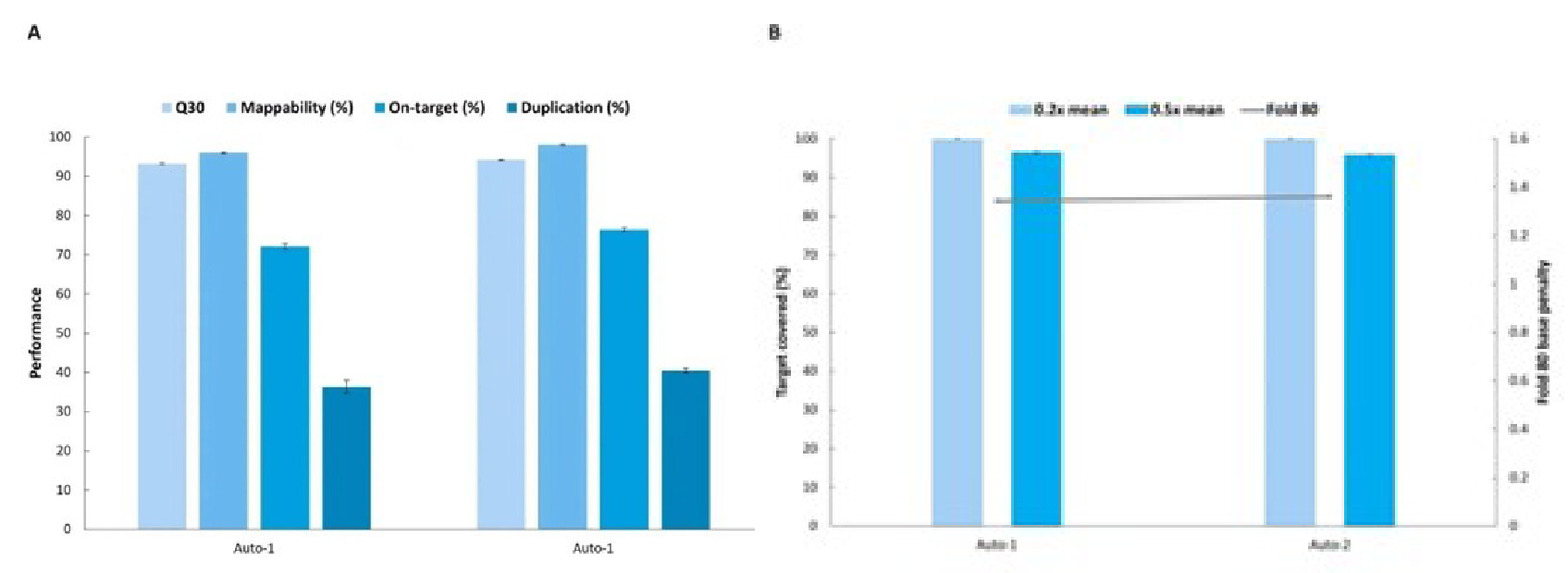

The average mappability of the two batches of captured data reached over 95%, showing good reproducibility, with on-target rates maintained at above 72%, meeting quality inspection requirements (Figure 7.A). In addition, the 0.2x mean of the target regions reached 99%, the 0.5x mean reached 95%, and the Fold 80 were also well controlled below 1.4, showing excellent coverage uniformity (Figure 7.B). As can be seen in Figure 8., a total of 16 reactions in the two batches of hybridization capture show no significant GC bias.

Figure 7. Capture performance of multiple-batch on NadAuto-16R. A. Q30, mappability, on-target rate and duplication; B. Target covered. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module. 500 ng of pre-library input was used to complete hybrid capture with LungCancer Panel v1.0 and NadPrep ES Hybrid Capture Reagents (1 hr for hybridization).

Figure 7. Capture performance of multiple-batch on NadAuto-16R. A. Q30, mappability, on-target rate and duplication; B. Target covered. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module. 500 ng of pre-library input was used to complete hybrid capture with LungCancer Panel v1.0 and NadPrep ES Hybrid Capture Reagents (1 hr for hybridization).

Figure 8. GC bias of multiple-batch on NadAuto-16R. A. 1st batch; B. 2nd batch.

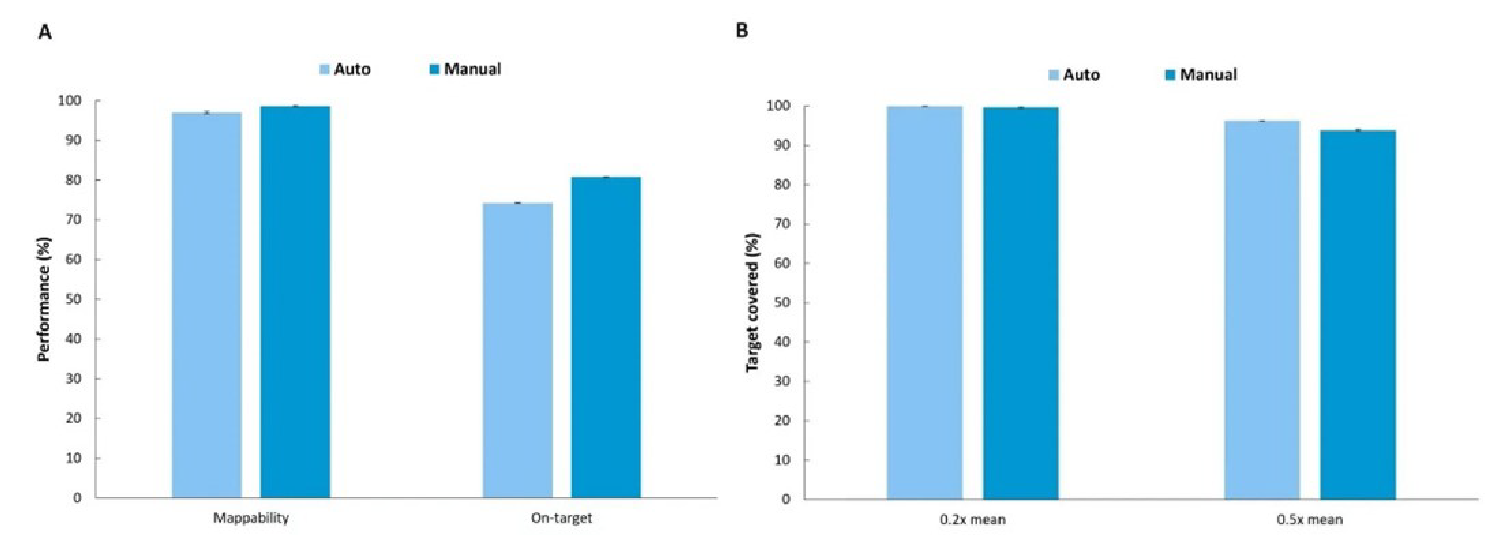

4.2.4 NadAuto-16R vs. manual operation

In addition, we compared the performance of automated and manual operation in capture data. Figure 9. showed that under the same experimental conditions and parameters, there were no significant differences between the two in terms of mappability, on-target, and target covered.

Figure 9. Comparison of capture performance between NadAuto-16R Fully-automated and manual operation. A. Mappability and On-target; B. Target covered.

With the continuous advancement and widespread application of Next-Generation Sequencing (NGS) technology, both research and clinical practice have raised higher demands for the automation, stability, efficiency, and safety of experimental processes. Traditional manual operations in NGS workflows face various challenges, such as cumbersome process, complex operations, high requirements for personnel expertise, low throughput per single operation, and the risk of cross-contamination in open operating environments. Therefore, there is an urgent need in many laboratories for a new, higher level of automation in NGS workstations to extend unmanned operation time and reduce labor and time costs. NadAuto-16R Fully-automated NGS Workstation (hereinafter referred to as "NadAuto-16R") has emerged to meet this demand, combining extensive experience in NGS reagent development and usage to better fulfill the need for automation in the complex NGS workflow.

The launch of NadAuto-16R stems from a profound understanding of wet lab experiments in the entire NGS workflow and insights into the challenges in experimental operations. It is specifically designed by Nanodigmbio for the NGS applications, aiming to provide a more efficient and precise experimental tool to meet the market demand for high-throughput, high-quality experiments.

The end-to-end solution based on NadAuto-16R not only enhances the standardization level of experimental operations but also improves the efficiency of the experimental process while significantly reducing errors introduced by manual operations. NadAuto-16R is dedicated to providing researchers with a more intelligent and reliable experimental solution, empowering them to achieve more significant accomplishments in NGS applications.

Figure 1. NadAuto-16R Fully-automated NGS Workstation.

NadAuto-16R consists of a host, integrated terminal, and control software. The host comprises a 3D robotic arm, a liquid handling module, 2 temperature control modules, a thermal cycler, a heating and oscillating module, and a host frame. The host has 12 standard SBS built-in plate positions, allowing for the flexible combination of functional modules, carrier, and consumables to meet the needs of various scenarios and sample amounts. Meanwhile, it is accompanied by a liquid handling module with 8-channel pipetting tips and a plate gripper, supporting the loading of 1/8 pipette tips, enabling flexible configuration based on the samples amounts, thus enhancing efficiency and facilitating plate transfer effortlessly.

Figure 2. Dynamic deck layout for NadAuto-16R.

NadAuto-16R is not only applicable to automated sample processing and loading, including sample dispensing, nucleic acid extraction, enzyme reaction system preparation, nucleic acid purification, quantitative loading, and sample mixing, but also for automated preparation of gene sequencing libraries and hybridization capture in clinical diagnostics, which can comprehensively enhancing laboratory efficiency.

Figure 3. Application of NadAuto-16R.

Compact and Portable

Occupies less than 1 m3 of desktop space, effortlessly fits in limited spaces.

Integrated design of terminal all-in-one and mainframe, saving installation and operational space.

Flexible Integration

Seamless integration of temperature control module, heating and oscillating module, and thermal cycler on the dynamic deck, supporting the flexible configuration of high-throughput workstation to true walk-away automation.

Multi-functional integrated modules create a professional-level NGS automated workstation with minimal user errors.

Flexible combination of 8-channel pipetting tips for precision pipetting, meeting diverse liquid-handling requirements, and improving pipetting efficiency.

User-friendly Simplicity

3D Mobile Robot with 8-channel pipetting tips and plate gripper, equipped with preset multiple transfer tracks, effortlessly handling liquid transfers and plate movements.

High-definition large LCD screen, flexible touch control with quick response, one-touch start/pause/resume processes to sustain workflow.

Graphical process editing, guided operation, drag-and-drop script elements, zero-threshold visual programming for a more user-friendly human-machine interaction.

Preset for routine applications such as NGS library preparation and hybridization capture, ready to use upon purchase. Meanwhile also supporting personalized customization and independent script development.

Secure and Reliable

Standard equipped with HEPA and UV lamp, ensuring continuous cleanliness of the operating environment.

Based on a liquid-free air displacement pipetting principle, effectively removing aerosol contamination.

Bright, highly colored status light bar indicates the host's operating status in real time, thus avoiding hardware failures and software errors that can cause long downtime.

Multi-level permission management ensures data security by assigning different operation permission levels to various users.

Emergency pause button is available for one-touch emergency stop, ensuring human-machine safety.

NadAuto-16R is compatible with full series of library preparation and hybridization capture reagents from Nanodigmbio. Based on the built-in scripts of the instrument, it can deal with a throughput of up to 16 samples per run for library preparation and 16 reactions per tun for hybridization capture. In addition to reagent preparation and library quality control, it essentially achieves fully automated wet experimental operations, extending unattended operation time to improve work efficiency.

Figure 4. Entire process of pre-library preparation and rapid hybridization capture on NadAuto-16R

4.1 Experimental DesignAutomated operations are performed on NadAuto-16Rutilize built-in scripts of the instrument. All manual operations are performed in accordance with the user manual.

Hybridization capture: The multi-hybridization reaction was initiated with 500 ng of each pre-library with the same pre-library preparation scheme. Thecapture was performed by using LungCancer Panel v1.0 with NadPrep ES Hybrid Capture Reagents (1 hr for hybridization). 8 samples per batch. 1 Gb of data was selected for analysis.

Table 1. Complement reagents of automated NGS application on NadAuto-16R.

4.2 Performance

4.2.1 Performance of pre-library preparation in different batches (8 samples per batch fragmentated by sonication)

Pre-libraries preparation were performed in each batch using 50 ng and 100 ng of human genomic DNA standards (Promega, G1471) fragmentated by sonication respectively, with 8 samples per batch. The results showed good stability of library yield across different batches, with average library yield ranging from 1192.9 ng to 1,409.6 ng (Figure 5.A), and the CV value (%) ranging from 2.826 to 4.650. In addition, after library preparation in each batch, we randomly selected 2 libraries for Qseq quality inspection (Figure 5.B), which showed that the size distribution of insert fragments in the libraries was within the expected range, consistent with the parameters recommended in the user manual.

Figure 5. Multiple-batch library yield and size distribution of the whole-genome libraries with sonication fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA Library Preparation Kit (for Illumina®) coupled with the NadPrep Universal Stubby Adapter (UDI) Module.

Figure 5. Multiple-batch library yield and size distribution of the whole-genome libraries with sonication fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA Library Preparation Kit (for Illumina®) coupled with the NadPrep Universal Stubby Adapter (UDI) Module.4.2.2 Performance of pre-library preparation in different batches(8 samples per batch fragmentated by enzyme)

The results showed good stability of library yield across between 6 batches, with the average library yield ranging from 1473.6 ng to 1,848 ng (Figure 6.A), and the CV value (%) ranging from 3.068 to 6.566. In addition, after library preparation in each batch, we randomly selected 2 libraries for Qseq quality inspection (Figure 6.B). The results showed that the insert fragment distribution of the libraries was within the expected range, consistent with the parameters recommended in the user manual.

Figure 6. Multiple-batch library yield and size distribution of the whole-genome libraries with enzymatic fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module.

Figure 6. Multiple-batch library yield and size distribution of the whole-genome libraries with enzymatic fragmentation on NadAuto-16R. A. Library yield; B. Size distribution. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module.4.2.3 Performance of captured library preparation in different batches (8 samples per batch)

The average mappability of the two batches of captured data reached over 95%, showing good reproducibility, with on-target rates maintained at above 72%, meeting quality inspection requirements (Figure 7.A). In addition, the 0.2x mean of the target regions reached 99%, the 0.5x mean reached 95%, and the Fold 80 were also well controlled below 1.4, showing excellent coverage uniformity (Figure 7.B). As can be seen in Figure 8., a total of 16 reactions in the two batches of hybridization capture show no significant GC bias.

Figure 7. Capture performance of multiple-batch on NadAuto-16R. A. Q30, mappability, on-target rate and duplication; B. Target covered. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module. 500 ng of pre-library input was used to complete hybrid capture with LungCancer Panel v1.0 and NadPrep ES Hybrid Capture Reagents (1 hr for hybridization).

Figure 7. Capture performance of multiple-batch on NadAuto-16R. A. Q30, mappability, on-target rate and duplication; B. Target covered. Pre-libraries were prepared using NadPrep DNA EZ DNA Library Preparation Module v2 coupled with NadPrep Universal Stubby Adapter (UDI) Module. 500 ng of pre-library input was used to complete hybrid capture with LungCancer Panel v1.0 and NadPrep ES Hybrid Capture Reagents (1 hr for hybridization).

Figure 8. GC bias of multiple-batch on NadAuto-16R. A. 1st batch; B. 2nd batch.

4.2.4 NadAuto-16R vs. manual operation

In addition, we compared the performance of automated and manual operation in capture data. Figure 9. showed that under the same experimental conditions and parameters, there were no significant differences between the two in terms of mappability, on-target, and target covered.

Figure 9. Comparison of capture performance between NadAuto-16R Fully-automated and manual operation. A. Mappability and On-target; B. Target covered.

Solutions

- Methyl Library Preparation Total Solution

- Sequencing single library on different platform--Universal Stubby Adapter (UDI)

- HRD score Analysis

- Unique Dual Index for MGI platforms

- RNA-Cap Sequencing of Human Respiratory Viruses Including SARS-CoV-2

- Total Solution for RNA-Cap Sequencing

- Total Solution for MGI Platforms

- Whole Exome Sequencing

- Low-frequency Mutation Analysis

Events

-

Exhibition Preview | Nanodigmbio invites you to join us at Boston 2025 Annual Meeting of the American Society of Human Genetics (ASHG)

-

Exhibition Preview | Nanodigmbio Invites You to Join Us at WHX & WHX Labs Kuala Lumpur 2025, Malaysia International Trade and Exhibition Centre in Kuala Lumpur

-

Exhibition Preview | Nanodigmbio Invites You to Join Us at Hospitalar 2025, Brazil International Medical Device Exhibition in São Paulo

-

Exhibition Preview | Nanodigmbio invites you to join us at Denver 2024 Annual Meeting of the American Society of Human Genetics (ASHG)

-

Exhibition Preview | Nanodigmbio invites you to join us at Sapporo 2024 Annual Meeting of the Japan Society of Human Genetics (JSHG)

-

Exhibition Preview | Nanodigmbio invites you to join us at Association for Diagnostics & Laboratory Medicine (ADLM)